Phenolic resins for the foundry industry

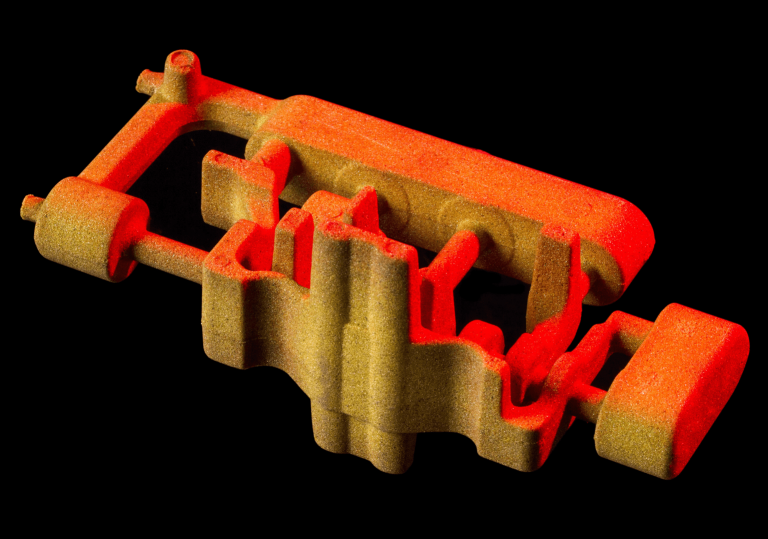

Foundry resins are used as sand binders in foundries to make cores and molds for small and large castings. Iron, steel or non-ferrous metals are used as casting materials. The desirable curing properties of these materials allow their use in highly modern and automated equipment. The various core and mold manufacturing processes are based on chemical casting technology, and our binders are continuously adapted to process changes and rationalization measures, meeting workplace and environmental protection requirements.

FENOLIT offers a range of different binders made from phenolic and furan resins under the brand names BOROFEN® and BOROFUR® for:

1. NO BAKE process (cold curing with direct addition of hardener)

- Furan No-Bake: process for all types of castings; good handling and processing properties; different furfuryl alcohol and nitrogen contents.

- Phenolic No-Bake: economical alternative to the Furan No-Bake process; higher thermal stability; slower curing can be compensated by the choice of an appropriate hardener; low phenol, nitrogen and formaldehyde levels

- Ester No-Bake (Alpha-Set): recommended for steel casting; nitrogen and sulfur free; possibility of using chromite or olivine sand (alkaline molding matrices)

Applications: heavy casting, steel casting, ductile iron casting, grey cast iron

2. GAS-CURING process (cold curing by gases)

- Cold-box: wide range of applications, long shelf life even when using regenerated sand, longer cleaning intervals, high degree of immediate strength, low sensitivity to moisture influences

- Beta-Set (MF Cold-Box process): nitrogen and sulfur free; no resin build-up in the core of the box; no glossy carbon formation; high thermal stability; particularly suitable for steel casting

- Resol CO2: similar properties to beta-set; CO2 gas does not cause problems; alternative to beta-set and water-glass processes

Applications: batch casting, heavy casting, steel casting, ductile iron casting, grey cast iron

3. Hot and warm sand coating (Croning or Shell Molding Process)

- For hot coating, phenolic resins are available as flakes or pastilles with low powder content, for hot cladding, resin solutions in methanol are available.

Applications: batch casting, steel casting, ductile iron casting, grey