Phenolic resins for abrasives

The grinding and cutting process has become an essential activity in many industries due to the mechanization of processes. Phenolic binders have proven to be the most suitable in this field of application for many years. Not only their favorable high-temperature and wear properties are important, but also a number of other properties, such as good resistance to chemical reagents during wet grinding.

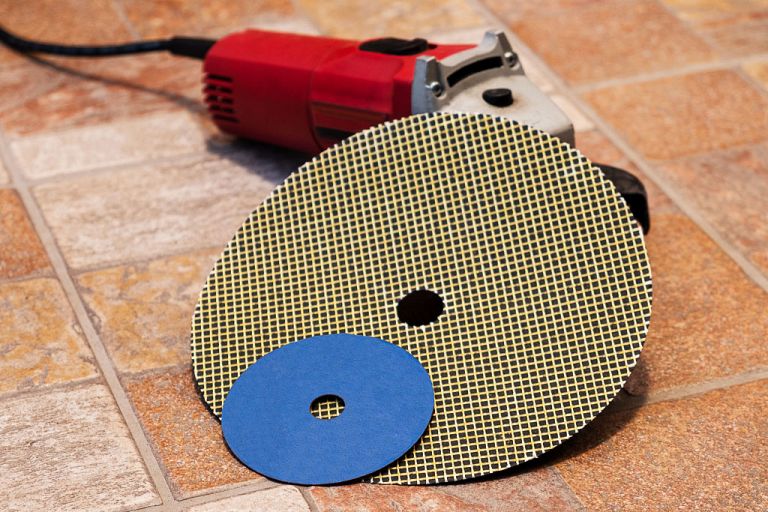

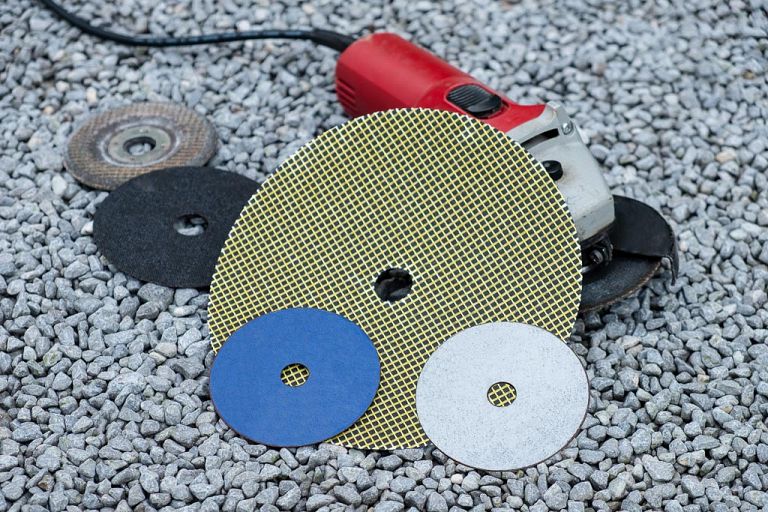

Unmodified powdered phenolic resins and epoxy-modified powdered phenolic resins for the manufacture of cutting and grinding wheels:

For the production of bonded abrasives, finely ground phenolic resins of the novolak (and epoxy modified) type with the addition of hexamethylene tetramine (and dust suppressant) in combination with a liquid resin are used. The abrasive grains shall be mixed with the liquid phenolic resin in such a way as to moisten all the grains. Powdered resin and additives are then added. The resulting mixtures are cold pressed and subsequently heat treated.

Liquid phenolic resins for abrasive grains:

An aqueous solution of a phenolic resin of the resol type is used for the production of cold-pressed abrasives and cut-off wheels, in combination with a novolak phenolic resin powder with hexamethylene-tetramine. They are used as a wetting and adhesion agent for the abrasive grains and are added to the abrasive in a mixer in such a quantity that all the grains are wetted equally with a thin layer of resin. The additives and powder resin shall then be added. With the right proportions of all the ingredients, a dry and gritty mass is formed which can still be pressed into shape-retaining discs. The abrasive discs are then finally cured in the oven.

Phenolic resins for glass fabric meshes:

A modified liquid phenolic resin dissolved in methanol is a binding resin for impregnating glass fiber mesh.

Liquid phenolic resins for coated abrasives:

The adhesive used to bond the abrasive grains to the substrate is an important factor in the manufacture of abrasive papers and other coated abrasives. Phenolic resins are mainly used in areas where water and temperature resistance are required.

As a supplier to the abrasive industry, Fenolit d.d. markets products under the brand names BOROFEN® and BOROSEC®. These are widely used in the production of high performance coated abrasive products on various substrates such as paper and fabric. Our products offer strong, resilient and durable bonds between grains, fillers and other ingredients in wet or dry conditions.

FENOLIT offers a range of different suitable binders for coated paper manufacturers under the brand names BOROFEN® and BOROSEC®, namely unmodified and modified phenolic resin resin types to meet customer needs in terms of the type of substrate used, the coating and bonding effect of the binder, the binder content, the curing parameters, the emission requirements and the flexibility of the final product.